VW Type 3 600 l - the highwayman

1. at the starting point: a media man and (his) crazy idea.

On his Instagram account, journalist Alexander Bloch describes himself as an automotive nerd, engineer and explainer, tester and presenter for VOX auto mobil and chief reporter for the specialist magazine auto motor und sport. So the media man is full of ideas by profession - and this is especially true when it comes to creative Volkswagens with Porsche DNA: air-cooled, of course, that almost goes without saying. For some time now, Bloch has been pursuing the idea of creating a VW 1.600 L - a Type 3, often referred to as the "VW Beetle for advanced users" - for his VOX auto mobil programme and then raffling it off among the viewers. According to Bloch's vision, a 3.6-liter Porsche engine with more than 300 hp was to do duty in the notchback model with a suspended rear section - knowing full well that the Biedermann from the sixties was never really designed for this. An expert, a connoisseur of the subject matter, was needed. But where was he to be found? The Type 3 Club had an obvious answer. The club referred us to one of its active members, the journalist Thorsten Elbrigmann. After an initial contact was made between colleagues, the name Christian Wilms soon came up. The owner of dtw germany | das triebwerk in Schwelm and Elbrigmann had known each other for years. They had been hanging out with the "street robbers" at countless events - the best conditions for launching an unusual project. Theoretically at least.

2. from theory to practice: a cool powerhouse is created.

As far as more serious Type 3 conversions were concerned, Christian Wilms was indeed able to point to a repertoire of - conservatively estimated - 18 similarly demanding projects. And so the spectrum ranged from turbo performance upgrades with a quarter-mile background to exactly the technology and performance the editors had in mind. After an in-house visit to dtw germany | das triebwerk , the decision was made: "This thing has to go in the box!" As the instigator, Alexander Bloch was of course on site with the production team from VOX auto mobil in Schwelm for the first shoot to accompany the stocktaking. The first task was to find the right basis for the conversion. At this early stage, nobody suspected that Walter Röhrl, who had already competed in rallies and the Porsche Sports Cup with Stephan Rohleder, the second owner of the engine, would test the result extensively on the racetrack. Christian Wilms says: "When we think back on it today, we realize what madness we were up to. What we didn't quite realize at the beginning were all the technical hurdles that would have to be overcome in order to actually be able to install a six-cylinder boxer engine." Massive modifications to the bodywork were necessary. The revision of the Porsche engine was the least of the problems. The consequence: numerous night shifts. The pure construction time was nine months - or 1,200 to 1,300 working hours - which were rich in insights and experience.

3. power transmission: a central, challenging chapter

From the outset, the parties involved agreed on an undivided rear axle tube. In view of the targeted 300 hp engine output, it was not to be cut under any circumstances. The use of a longer Porsche five-speed manual gearbox with the G50 code was therefore not an option. Instead, intensive consideration had to be given to how the Carrera engine could be combined with a four-speed VW Beetle gearbox. The gear wheels of the South African version of the VW Bus and the stiffer, more heavily ribbed housing seemed to be the most suitable. It was also clear from the outset that two semi-trailing arms similar to the Porsche 911 would be indispensable on the rear axle. Christian Wilms had been able to gather corresponding experience with his own VW Type 3. In addition, the Porsche drive set would be significantly heavier than the previous one. His solution was to weld semi-trailing arm shoes to the pendulum axle subframe and mount them on cup struts. All this was necessary in order to achieve greater stability - especially as the semi-trailing arm suspension does not have a frame fork. The gearbox itself was not a problem. Christian Wilms had already bolted together several stable quarter-mile units and was sure that he could make the gearbox durable for the expected torque. Adjusting the gear ratio was also no problem. However, flange-mounting the six-cylinder boxer engine proved to be a real challenge.

4. special designs: essential for a clean power flow.

"All in all, it was quite a tough job" - with these words, Christian Wilms sums up the work on the drive components. Ultimately, the task was to find a clutch that would be able to transmit the high torque of the 3.6-liter boxer engine. A suitable flywheel did not exist: it had to be designed on the screen and produced as an exclusive custom-made product on the in-house machines in a second step. It also seemed imperative to convert the clutch, similar to the Porsche G50 gearbox, to a hydraulic actuation system with an adapted pedal mechanism - another problem that could be overcome over time. Another indispensable component in the drivetrain: the Torsen worm-roller differential - and suitable drive shafts. In another Type 3 with a special turbocharger retrofit, Christian Wilms very quickly put an end to the standard shafts. "They looked like corkscrews when I really got to grips with them at the airfield in Mendig," he documents. "Of course, that was another important 'aha' moment that took me a step further. I now knew that 2.4 liters of displacement and a turbo in the VW 1,600 L would entail special measures." And so he gets down to facts and figures: "In purely mathematical terms, 250 km/h is also feasible with the four-speed gearbox - but it's no fun above 200 km/h, there's no aerodynamic downforce at the rear. There's no pressure from a wing. We have built accelerators for the quarter mile and not for the high-speed range."

As a source of ideas, Alexander Bloch advised right from the start to get specialists on board. For the chassis, it was Bilstein - not far from the Schwelm site - with its team of experts. For the wheels, it soon became clear that a set of Fuchs rims would be needed. And for the brakes - yes, the brakes - more on that later! First of all, the "Bilsteiner" from nearby Ennepetal arrived to take measurements. Their approach was to put together an "MDS" suspension with adjustable rebound and compression damping. Given the space available, this was no easy task. Nevertheless, the shock absorbers were delivered quite quickly. Once the length had been adjusted, they simply fitted perfectly - everyone involved was very excited to see how the road robber, based on a 1968 VW 1.600 L, would feel with the new sports suspension. When the car was finally on its wheels and the engine was fitted, it became clear that other torsion bars would also have to be purchased. The slightly thicker version of the Type 3 in the estate version was far from adequate. The brake system came as a bit of a shock. The TÜV stipulated that it had to be the brake system from the Porsche Carrera 2. How was that supposed to work? Not at all with Fuchs rims in 15-inch sizes! So Christian Wilms once again sat down at his PC to design. The steering knuckle saddle mounting had to be milled off and a special aluminum hub part, suitable for the VW wheel bearings, had to be turned and drilled. In addition, suitable brackets were needed for the huge brake callipers - all with the blessing of the TÜV. How fortunate that Christian Wilms had acquired professional turning and milling skills before founding dtw germany | das Triebwerk...

5. chassis and braking system: two cases for real specialists.

A short stopover in Burscheid, where a specialist motorsport company has been machining Sachs, H&R and Bilstein suspension components for 40 years. It was there that Christian Wilms learned the skills of professional turning and milling. The contact was maintained even after the company was founded and Rolf, the (first) name of the Volkswagen specialist, is also TÜV-certified - a basic requirement for the next steps. All special parts had to be manufactured, including a strength certificate and the license to manufacture such components. A well-known principle applied to the installation of the brake system: the journey is the reward, and so some nights were long - or short. The rear axle required similarly immense effort, not to mention the double wishbone front axle based on a classic racing car. However, this made sense, as the six-cylinder boxer engine with the internal Porsche type designation M64/01, which already produced 250 hp, was to be given a few more horsepower. In key words: a freely programmable, digital engine management system, a proprietary fan manifold exhaust system and a single throttle valve system with open intake funnels, which was still under development at the time and is now used exclusively by dtw germany | das triebwerk on many different Porsche engines. The result: more than 300 hp - in retrospect, it is somehow obvious that a great deal of effort was required in the area of brakes and axles.

6. somehow obvious: major expenditure in the area of brakes and axles.

7 The interior: stylish, purist - a concert hall on wheels.

The interior was to be stylish and purist. With this goal in mind, Alexander Bloch made his way to Recaro to procure sports seats in a classic design. Dzezmin Aliti was on hand to carry out the saddlery work - he had already worked with the VOX editorial team several times in the past. The collaboration with the master craftsman from Cologne ran smoothly at all times. He delivered top-quality work at breakneck speed - everything really had to be perfectly coordinated in order to meet the tight deadline. Michael Zeitler from "Dr. Boom" in Cologne made his way to Schwelm to provide the right sound in the vehicle. The VOX editorial team was thrilled when they learned that a completely invisible sound system was planned that would transform the interior of the car into a rolling concert hall. At this point, it should be noted that the music system in the project VW 3.600 L is indeed the "top hammer". For Christian Wilms, true euphony always comes from behind - but he has to admit that "Dr. Boom" has conjured up a veritable firecracker. His conclusion: "You feel like you're sitting in a nine-eleven in our mugger - quite different from a VW Beetle, for example, despite all the technical parallels." It really is as the experts say: The VW 1,600 L is the Beetle for advanced drivers - and this VW 3,600 L even more so!

And then there was ...

... a two-time world rally champion. Walter Röhrl, who won titles in 1980 and 1982, is not just a friend of the company. The tall Bavarian from Sankt Englmar took the opportunity to test drive the extraordinary Project Type 3 and is said to have been very impressed, particularly by the directness of all the dynamic reactions. Possible motto: Röhrl. Approved. Once again.

8. the technical documentation in every detail

VEHICLE TYPE: VOLKSWAGEN 1,600 L, DTW CONVERSION TO PERFORMANCE VERSION 3,600 L - INSPIRED BY ALEXANDER BLOCH.

Model year of the base vehicle: 1968

Body (standard scope of delivery from the factory): Sheet steel, body on central tubular frame

Bodywork (dtw | das triebwerk ): complete restoration including repainting in "Golf blue"; relocation and widening of the inner wheel arches for later use of 16-inch Fuchs wheels; rear carrier extensively modified; engine mounts analogous to Porsche 911 (generation 964); cooling air intake adapted; external refueling in the front fender converted to internal refueling (analogous to model years up to 1967)

Lighting: front LED headlights (Kaege, originally designed for VW Golf I); original rear lights

Electrics: specially manufactured engine wiring harness; original complete vehicle wiring harness

Base engine: overhauled six-cylinder light-alloy boxer type M64/01 (MY 1991, version ex works already with cylinder head gaskets); two valves per cylinder; drive of the two camshafts via timing chain; specially manufactured dry sump oil tank; oil level sensor taken from the Carrera 2 (964) and connected to the fuel tank display via a changeover switch - selectable via a switch under the dashboard: The engine oil level can be read via the fuel gauge on the dashboard; engine control via DME (Motronic)

Engine design (dtw | das triebwerk ): individually manufactured, CNC-milled single throttle valve system from solid aluminum (adaptive, fits every six-cylinder boxer engine from 911 S 2.4 upwards); open intake funnels, open sports air filter; freely programmable, digital engine management, own manifold exhaust system with single throttle valve system

Engine output (dtw | das triebwerk): 333 hp at 6,900 rpm from 3,600 cc displacement

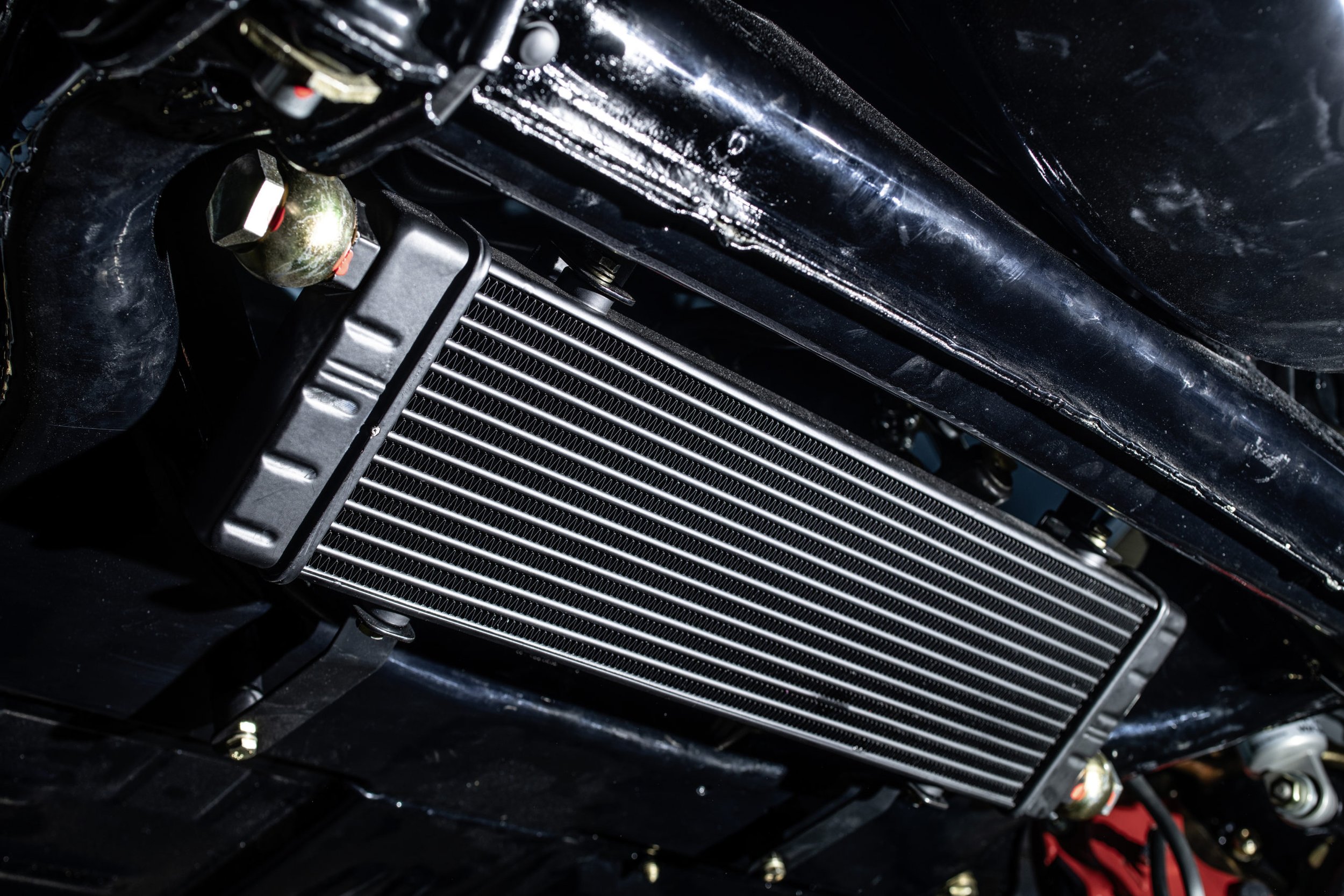

Power transmission: manually shifted, modified four-speed gearbox from the Volkswagen Beetle in South African design, reinforced by stronger ribbing; reinforced gear wheels; Torsen worm-roller limited slip differential; custom-made, specially turned flywheel; reinforced, hydraulically actuated clutch with adapted pedal mechanism; drive via specially configured drive shafts to the rear wheels

Brake system: original Porsche 911 Carrera 2 (964 generation) light alloy fixed calliper housing; specially manufactured/milled steering knuckle calliper mountings; special aluminum wheel hub parts, turned and drilled to fit the Volkswagen wheel bearings; specially manufactured brake calliper brackets with TÜV approval

Wheel suspensions (front, standard): Double wishbone axle, transverse torsion bars

Wheel suspensions (rear, standard): Swing axle, trailing arm, compensating spring, transverse torsion bars

Wheel suspensions (new, dtw | das triebwerk): Bilstein "MDS" shock absorbers (MDS = Modular Damper System), adjustable in rebound and compression damping; reinforced torsion bars type Porsche 944 turbo; front conversion to double wishbone axle; rear conversion to semi-trailing arm axle analogous to Porsche 944; suspension stool rigidly bolted to the body; aluminum "cup" struts for support; trapezoidal reinforcements; replacement of the permanently elastic mounting with specially manufactured turned parts with TÜV strength certificate

Wheels: Fuchs (16-inch, analogous to Porsche 911)

Tires: 185/55-16 front and 195/60-16 rear

Interior: Recaro sports seats in classic design; upholstery work by Dzezmin Aliti, Cologne

In Car Entertainment: invisible sound system from "Dr. Boom", Michael Zeitler

Unladen weight (standard): 920 kg

Unladen weight (new): 1,036 kg

(Theoretical) top speed: 250 km/h (0.82 fourth gear)

Acceleration: 0 - 100 km/h in 3.5 seconds

Construction time: 9 months; 1,200 - 1,300 working hours